Equipment name: Microcomputer controlled bone screw torsion testing machine

Models: CTT4101, CTT4201, CTT4501, CTT4102

Product Overview: The TTM-201 electronic torsion testing machine for bone screws is suitable for testing and analyzing the torsional mechanical properties of metal materials, non-metal materials, composite materials, as well as medical devices such as bone screws, biomaterial surgical implants, bone joint implants, intramedullary fixators, metal bone screws, hollow bone screws, etc. Can automatically calculate TeH, TeL, Tm τ EH τ EL τ M τ Test parameters such as p0.2 and G. Can meet special testing requirements of users. It can achieve closed-loop control such as constant rate loading, constant rate torque angle, and constant rate angle, and can conduct process qualification performance verification tests on materials or products. Equipped with a torsion angle extensometer, it can automatically calculate the shear modulus G, and the test results can be saved, queried, and printed.

Meet and apply standards

This testing machine is manufactured in accordance with GB/T 2611-2007 General Technical Requirements for Testing Machines, GB/T10128-1998 Metal Room Temperature Torsion Test Method, and JB/T9370-1999 Technical Conditions for Torsion Testing Machines.

Inspection standard: JJG269-2006 Torsion Testing Machine

Test method: YY/T0018-2016 "Metal bone screws for bone grafting implants"

YY/T0662-2008 "Mechanical Performance Requirements and Test Methods for Metal Bone Screws with Asymmetric Thread and Spherical Undersurface Metal for Surgical Implants" ISO 6475:1989 "Implants for surgery - Metal bone screws with asymmetric thread and spherical undersurface - Mechanical requirements and test methods"

YY/T0345.1-2011 "Surgical Implants Metal Bone Nails"

YY/T0591-2011 Metal interlocking intramedullary nails for bone joint implants

YY/T1505-2016 "Test method for self tapping performance of metal bone screws for surgical implants"

YY/T1506-2016 "Test method for rotational torque of metal bone screws for surgical implants"

This testing machine was calibrated and accepted in accordance with the JJG 269-2006 Verification Regulations for Torsion Testing Machines.

Applicable standards: Conduct tests and provide data in accordance with international standards such as GB, ISO, DIN, ASTM, JIS, BS, etc.

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

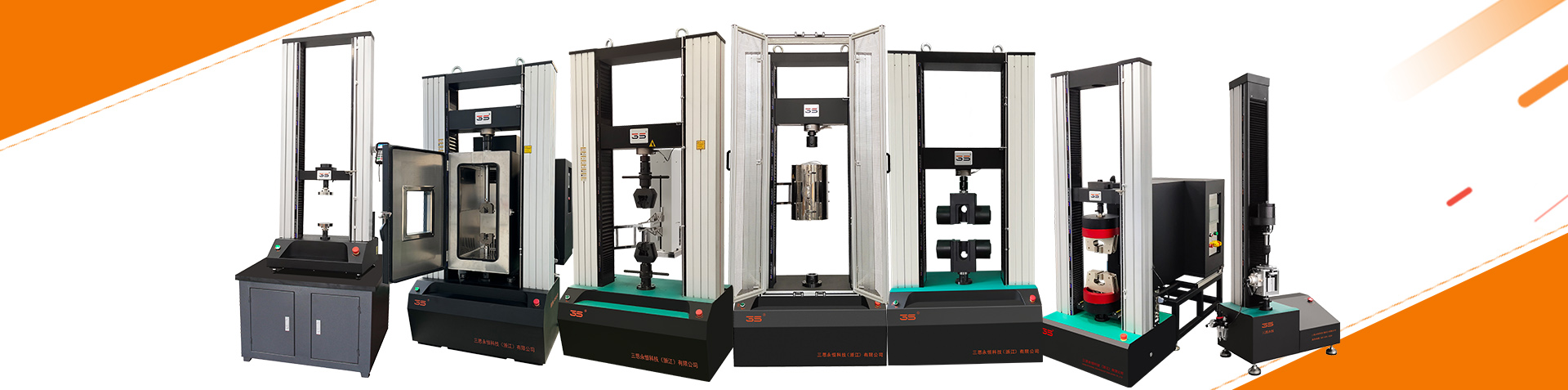

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument