Equipment name: Microprocessor controlled electronic universal testing machine (dual space)

Main functions of the device: This device is suitable for testing the mechanical properties of metal materials, metal materials, and composite materials, as well as analyzing and researching the technical properties. Equipped with corresponding equipment, it can perform tests such as tension, compression, bending, shearing, tearing, peeling, bursting, fatigue, etc. The maximum test value, fracture value, elongation, tensile strength, yield strength, compressive strength, elastic modulus, shear strength, tear strength, peel strength, and other parameters can be automatically calculated. At the same time, it can also achieve testing requirements such as constant elongation, constant elongation, and load retention, with three closed-loop control methods of stress, strain, and displacement. This machine is widely used for material inspection and analysis in industries such as building materials, aerospace, mechanical manufacturing, wire and cable, rubber and plastic, automotive manufacturing, powder metallurgy, etc. It is a scientific research institution, vocational college, mining enterprise, technical supervision, etc Ideal testing equipment for departments such as commercial inspection and arbitration.

CMT3200 servo control system

Real time and dynamic display of the experimental process and curves, data processing through modular software, data reanalysis and editing of curve amplification, output of different formats of experimental reports and curve patterns, and support for online data transmission.

DCH80 is a manual control box equipped with a LCD display screen and an electronic universal testing machine controller CMT3200. This product supports displaying load, displacement, and displacement speed, and can perform simple operations on the electronic universal testing machine without the computer, such as fast up, fast down, slow up, slow down, return, sample protection, etc.

The all-new DCH80 series LCD control panel includes a set of functional control keys and a real-time display screen, simplifying experimental steps and improving data reproducibility;

Real time display of experimental data, including force, displacement, displacement speed, etc., reduces frequent switching operations between the operator panel and the industrial computer workstation, making it convenient for operators to conduct experiments accurately and efficiently;

Real time display of operating status, connection status of LCD operation panel, and movement direction of loading beam;

The precise positioning key, with a precise micro adjustment button with a jog anti lock function, can be configured with any speed using CMT3200 software. During sensitivity testing, the device can be controlled to move at a speed as low as 0.001/min.

The crossbeam loading and debugging mobile key controls the crossbeam loading to reach the test operation area smoothly and quickly, with stepless speed change operation and buffering protection function for loading and parking, greatly facilitating the rapid adjustment of the test bench and ensuring the long-term stable and efficient operation of the host.

After using the CMT3200 software to input the sample size and control plan in advance, the tester can leave the industrial computer workstation and complete the testing of all samples through the "Run", "Stop", and "Reset" keys on the control panel, improving the efficiency of the test.

Ergonomic innovative design, supporting new user experiences, with a large screen;

Main technical parameters of the equipment:

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

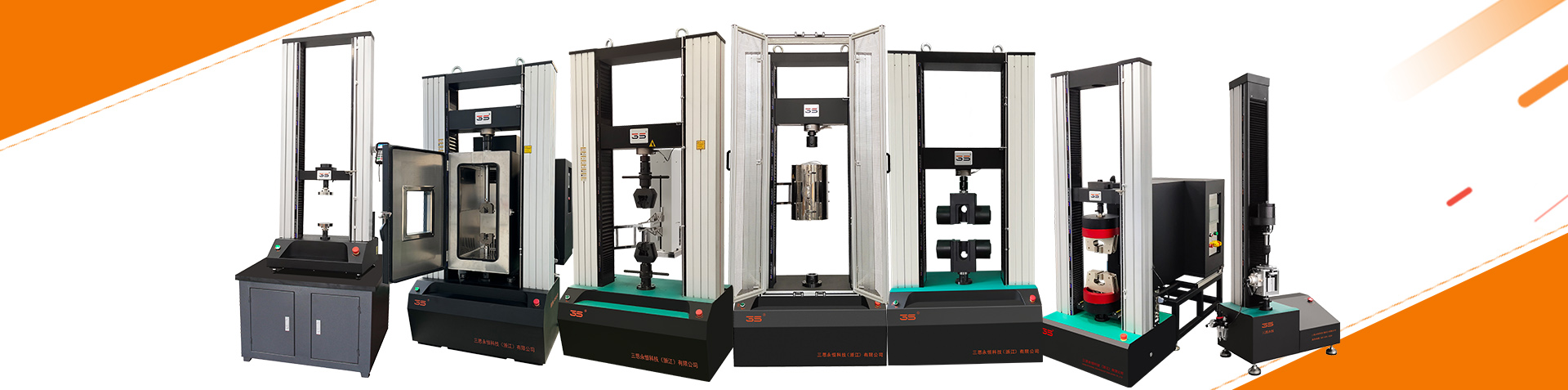

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument