Equipment name: Electro hydraulic servo fatigue testing machine

Equipment model: DMT2000

Equipment Overview:

The DMT2000 series electro-hydraulic servo fatigue testing machine is mainly used to test the static and dynamic mechanical properties of metal and non-metal materials. It can achieve mechanical tests such as tension, compression, tension, compression, and tension compression, as well as high cycle fatigue, low cycle fatigue, crack propagation, fracture toughness, and other tests. It can also output various waveforms such as sine wave, triangular wave, and square wave.

Performance characteristics:

The crossbeam is placed above and the actuator is placed below to form a closed frame structure. The frame has high stiffness, no reverse clearance, and good stability;

The actuator adopts a bidirectional oil cylinder design, with reasonable spatial design and convenient operation;

The lifting, locking, and sample clamping of the moving crossbeam are all operated by buttons, which are flexible and convenient.

Meets standards:

1) GB/T 2611 General Technical Requirements for Testing Machines

2) GB/T16825.1 "Inspection of static uniaxial testing machines - Part 1: Inspection and calibration of force measurement systems for tensile and/or pressure testing machines"

3) GB/T 16826 "Electrohydraulic Servo Universal Testing Machine"

4) JB/T 8612 "Electrohydraulic Servo Universal Testing Machine"

5) JB/T 9397 Technical Conditions for Tension Compression Fatigue Testing Machines

Technical parameters:

Model: DMT2254/DMT2504/DMT2105/DMT2255/DMT2505

Maximum load dynamic (kN): ± 25/± 50/± 100/± 250/± 500 Static (kN)/25/50/100/250/500

Measurement accuracy: ± 0.5% force better than indicated value/± 0.5% deformation better than indicated value/relative displacement accuracy better than 0.5% FS

Dynamic test frequency (Hz) 60/50

Experimental waveforms include sine wave, square wave, triangular wave, trapezoidal wave, oblique wave, custom waveform, etc

Test amplitude (mm): Determine the amplitude based on the displacement of the hydraulic oil source

Piston stroke (mm): 150 (± 75)

Control method: Three closed-loop control of force, displacement, and deformation |

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

Dynamic fatigue testing machine Electronic universal testing machine

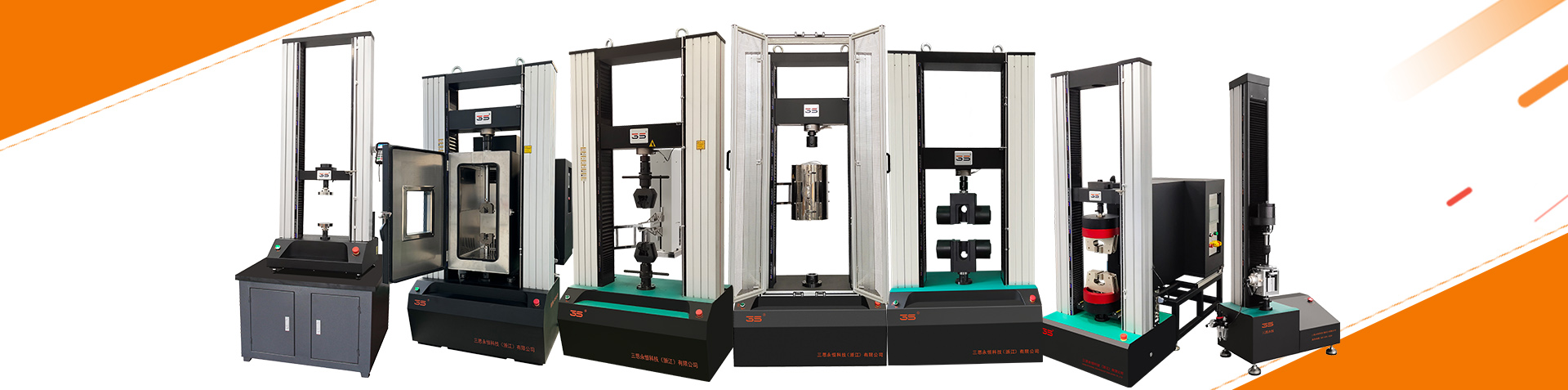

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument