Equipment name: Single space electro-hydraulic servo universal testing machine

Equipment model: SHT5305

Equipment Overview:

The SHT5305 microcomputer controlled electro-hydraulic servo universal testing machine has the characteristics of compact structure, simple and easy to use, and can be applied to tensile tests of metal bars and plates with a maximum load of 300kN, tensile tests of threaded steel, tensile bending and compression tests of high-strength bolts and high hardness metal materials. It has three control methods: load, deformation, and displacement, and can achieve smooth switching. It can achieve constant rate load control, constant rate deformation control, and constant rate displacement control.

The experimental software can automatically collect and process experimental data, display various experimental curves such as stress-strain curve, load deformation curve, load time curve in real time, and save, output, and print the user's required experimental reports and data.

Meets standards:

GB/T 2611 General Technical Requirements for Testing Machines

JJG 1063 "Electrohydraulic Servo Universal Testing Machine"

GB/T 16826 "Electrohydraulic Servo Universal Testing Machine"

GB/T 228.1 "Tensile testing of metallic materials - Part 1: Room temperature test method"

Technical parameters:

Specification and model: SHT5305

Maximum load (kN): 300

Accuracy level of testing machine: 0.5 level

Relative error of test force indication: within ± 0.5%

Measurement range of experimental force: 1% -100% FS (without dividing the entire process)

Deformation (extensometer) measurement range: 1% -100% FS

Relative error of deformation indication: ± 0.5%

Deformation resolution: 1/500000 of the maximum deformation amount

Maximum speed of piston upward movement (mm/min): 280

Maximum speed of piston descent movement (mm/min): 210

Test force loading rate range: 0.02% -2% FS/s

Effective distance between columns (mm): 520

Maximum spacing between stretching jaws (mm): 600

Maximum compression space (mm): 380

The clamping range of the circular specimen clamping block (mm): Φ 10~ Φ 18 Φ 18~ Φ thirty-two

Clamping thickness of plate specimen clamping block (mm): 2-15, 15-25

Pressure plate size (mm): ɸ one hundred and twenty

Piston stroke (mm): 350

External dimensions of the host (length x width x height, mm): 760x300x2202

External dimensions of oil source (length x width x height, mm): 1150x600x900

Power supply: three-phase five wire system 380VAC ± 10%, 50Hz, 4kW

Weight (kg): 1000 (main engine)+400 (oil source) |

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

Dynamic fatigue testing machine Electronic universal testing machine

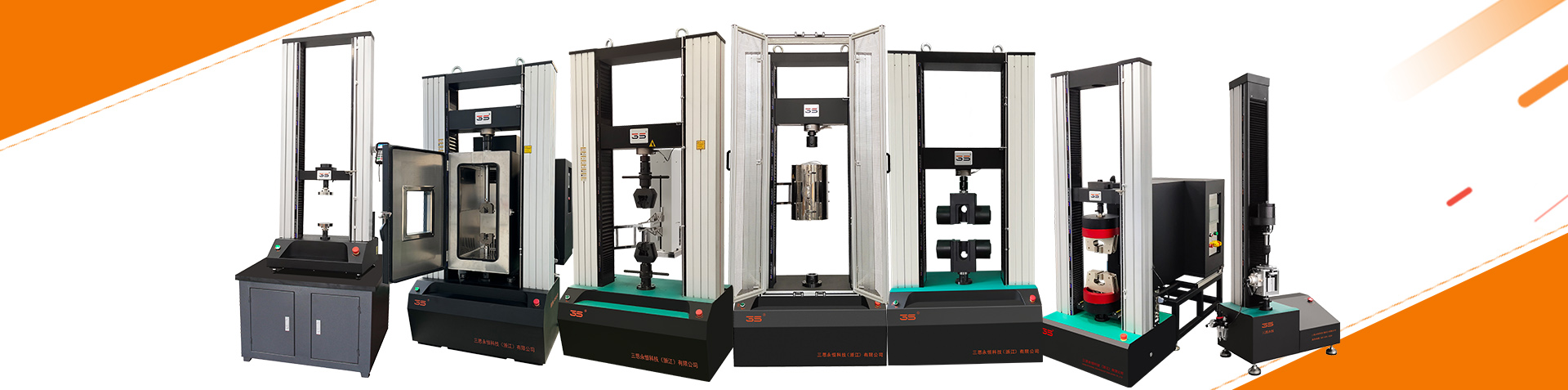

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument