Equipment name: Fully automatic melt flow rate testing machine

Model: ZRZ3452

Performance description:

This instrument meets the technical requirements of GB3682-2018 Test Method for Melt Flow Rate of Thermoplastics. Quality control is crucial for the production technology of medical and health protective materials such as medical masks, surgical gowns, and protective clothing, as well as polypropylene resin for melt blown polypropylene and anti stick nonwoven fabrics.

Its main parameters meet the requirements of ISO1133 and ASTM1238 standards and can be used to measure the melt flow rate of various materials such as polyethylene, polypropylene, polystyrene, ABS, polyamide, fiber resin, acrylic ester, polyoxymethylene, fluoroplastics, polycarbonate, etc.

Widely used in industries such as plastic raw materials, plastic production, plastic products, petrochemicals, and related colleges, research institutions, and inspection departments.

Execution standards:

ISO1133:2011(E)"Plastics - Determination of the melt mass – flow rate (MFR) and the melt volume – flow rate (MVR) of thermoplastics"、

GB3682-2018 "Determination of mass flow rate and volume flow rate of thermoplastic melts"

JB/5456-2016 Technical Specification for Melt Flow Rate Meters

JJG878-2005 Melt Flow Rate Instrument

Complies with GB/T3682, ISO1133, ASTM D1238, ASTM D3364, DIN 53735, UNI 5640, BS 2782, JJGB78 standards, and is manufactured in accordance with JB/T 5456 Technical Conditions for Melt Flow Rate Meters.

product mix

This instrument mainly consists of parts such as material cylinder, piston rod, mouth mold, temperature control system, load, automatic testing mechanism, and automatic cutting.

Main technical parameters and accuracy

1. Standard part parameters:

(1) Barrel parameters: Inner hole: Φ 9.550mm ± 0.007mm

(2) Piston parameters: piston head Φ 9.474mm ± 0.007mm

(3) Length of piston head: H=6.35mm ± 0.1mm

(4) Oral membrane inner diameter: Φ 2.095mm ± 0.005mm, half mouth mold: Φ 1.05mm ± 0.005mm

(5) Mouth film length (flow channel length): 8.00mm ± 0.025mm, half mouth mold: 4.00mm ± 0.025mm

2. Temperature control parameters:

(1) Temperature control range: 80 ℃~400 ℃;

(2) Temperature control accuracy: ± 0.2 ℃

(3) Display resolution: 0.1 ℃;

(4) Maximum power consumption: ≤ 1.5Kw

(5) Temperature recovery time: 4 minutes (GB)/6 minutes (ASTM)

3. Location detection:

(1) Distance between upper and lower positions: 30mm, (can be measured by displacement measuring device at 20mm, 10mm, 5mm, 3mm, 2mm, 1mm;)

(2) Control accuracy: ± 0.1mm

4. Equipment weight: 80kg

5. External dimensions: 500mm x 400mm x 1100mm (length x width x height)

6. Power supply: AC 220V 1.5Kw

7. Index range: (0.1-100) g/10min

8. Accuracy level: Level 1 |

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

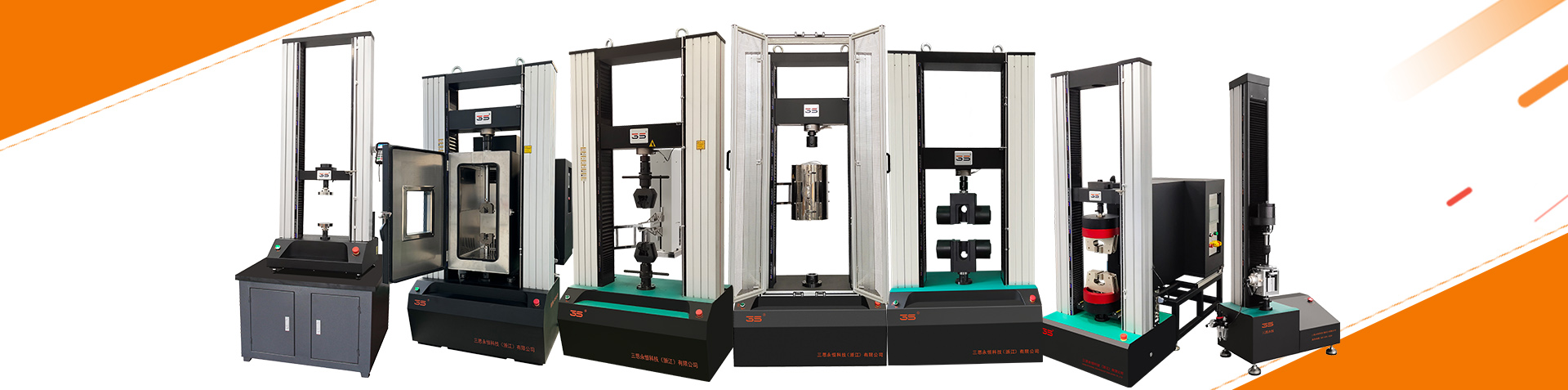

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument