Equipment name: ZRZ2000 touch screen melt flow rate testing machine

Equipment use: mainly suitable for measuring the melt mass flow rate and melt volume flow rate of thermoplastic materials.

Applicable standards

JJG878-2005 Melt Flow Rate Instrument

JB/T5456-2016 Technical Conditions for Melt Flow Rate Instruments

GB/T3682-2018 "Determination of mass flow rate and volume flow rate of thermoplastic melts"

ISO1133:2011(E)"Plastics - Determination of the melt mass – flow rate (MFR) and the melt volume – flow rate (MVR) of thermoplastics"

ASTMD1238-2013"Standard Test Method for Melt FloW Rates of Thermoplastics by ExtrusionPlastometer"

Performance characteristics

The host adopts a high-precision rotary encoder structure, which increases the sampling frequency and accuracy, and meets the displacement accuracy requirements of the new standard.

The furnace is made of copper with high thermal conductivity efficiency, and the outer diameter is thickened on the basis of the old model to improve the uniformity of the material barrel; The upper and lower partitions are made of polymer insulation materials, which enhance the overall insulation performance and are not too hot to touch;

Specially designed pressure rods, cleaning rods, die plugs, and die cleaning rods are convenient and highly practical.

The temperature controller adopts the Japanese Omron brand, with high accuracy and good stability.

The touch screen operation interface is clearer and more intuitive, and the operation is simple and easy to understand.

Equipped with a microcomputer controller specifically developed for melt finger testing machines; The entire process control, data processing, and data printing of the experimental process can be carried out, and the test results can be printed out through the equipped micro printer.

Equipped with an aluminum alloy weight box.

technical parameter

Equipment model: ZRZ2452

Temperature control range (° C): 50-450;

Temperature control fluctuation (° C):+0.2;

Temperature control 4-hour drift (° C): ≤+0.5;

Temperature control temperature gradient (° C): ≤ 0.5 ° C (from the upper end of the inner mold of the material barrel to the 70mm tropical zone);

Temperature control resolution (° C): 0.1;

Recovery time of barrel temperature after feeding (min): ≤ 4;

Timing clock range (s): adjustable from 0 to 6000;

Timing clock resolution (s): 0.1;

Cutting device: automatically complete cutting or jog cutting;

Mouth inner diameter (mm): φ 2.095 soil 0.005mm;

Inner diameter of material cylinder (mm): φ 9.550 ± 0.007mm;

Weight load accuracy: ≤ ± 0.5%;

Weight load range (g): 325-21600g discontinuous, the combined load can meet the standard requirements;

Measurement range: 0.1-2000g/10min;

External dimensions of the host (length x width x height mm): 550mm x 435mm x 735mm

Host power supply: AC single-phase 220V earth 10%, 50Hz |

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

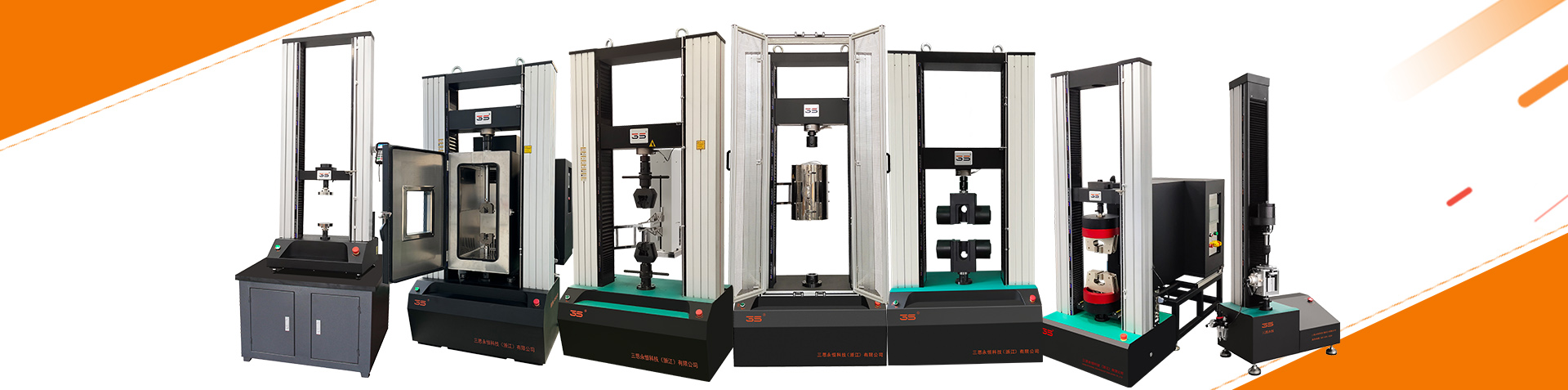

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument