Device Name:Electrolytic thickness gauge (excluding computer)

Equipment specifications:ET-3C

Equipment introduction and functional characteristics: The ET-3C electrolytic thickness gauge has the characteristics of structure, stable and reliable performance, and complete functions. The use of this instrument can ensure the product quality of user units and prevent waste of raw materials. This instrument can also help users find electroplating processes that are suitable for different requirements, which is an instrument chosen by finished product factories and electroplating factories.

Main functions and features:

1. This product uses independently developed chips to process data, with features such as high-speed serial port, high-speed A/D, precision, compatibility, anti-interference, long lifespan, and technical front-end;

2. Switching between Chinese and English interfaces for LCD display, with high display quality, digital interface, small size, light weight, low power consumption, etc;

3. The thermal printer needs to be used for a long time without replacing the ribbon. Micro printing interface for printing test reports in both Chinese and English, printing coating type, thickness, testing personnel, date, internal clock calendar, no need to set each time;

4. Automatically pause measurement prompt to replace electrolyte. To reduce measurement errors;

5. Automatically calculate the average value. Below 10 microns are three decimal places with an accuracy of 1/1000;

6. Can measure multi-layer plating such as Cr/Ni/Cu/plastic, the report can be printed out at once without the need for disassembly printing;

7. Using imported standard plates from the United States, calibration and calibration achieve ideal measurement error values. Adjustable conductivity coefficient reduces errors;

8. Adjust the endpoint potential difference to adapt to the appropriate potential between the coating and substrate;

9. By measuring more than 70 combinations of metal coating substrates, it can measure coatings on flat and curved surfaces, as well as small parts, wires, and linear parts;

10. Plating removal speed 0.3-40 μ M/minute adjustable;

11. The vacuum squeezing air pump circulates stirring, and the stirring force and gas volume can be adjusted according to the coating to achieve a suitable dissolution state,;

12. The electrolytic cup is made of corrosion-resistant alloy stainless steel, which is not prone to corrosion and aging;

13. Adjustable constant current to achieve suitable electrolysis efficiency;

14. The operation interface function matrix buttons are intuitive and convenient for operation and measurement, and input can be directly completed;

15. The matrix buttons use imported Omron or NKK, with a lifespan of over 10 million times;

16. The thickness gauge host adopts a high-speed USB interface for transmission and can be connected and compatible with various laptops, achieving better operational display. The software automatically captures accurate coating thickness curves with the machine. This model can test the copper plating function on copper. This model can be connected to a computer, and the curve direction can be observed. The results can generate office files for long-term storage and A4 paper printing reports;

17. Measurement of multi-layer nickel thickness and potential difference: This model of instrument can measure the total thickness of multi-layer nickel at once (nickel seal, pearl nickel, bright nickel, high sulfur nickel, semi bright nickel). Can analyze the thickness and potential difference of each layer of coating. For example: chromium/bright nickel/high sulfur nickel/semi bright nickel/nickel seal/Cu/plastic, while measuring the thickness and electrochemical potential of double-layer or three-layer nickel coatings. The ET-3 electrolytic thickness gauge has a high voltage resolution and can measure the potential between micro porous nickel or microcracked nickel on the top layer and bright nickel on the bottom layer, as well as the potential between bright nickel and semi bright nickel. (If necessary, it can also be high sulfide nickel between bright nickel and semi bright nickel); It is possible to measure the thickness of metal coatings on almost all metal or non-metal substrates, even in multi coating systems.

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

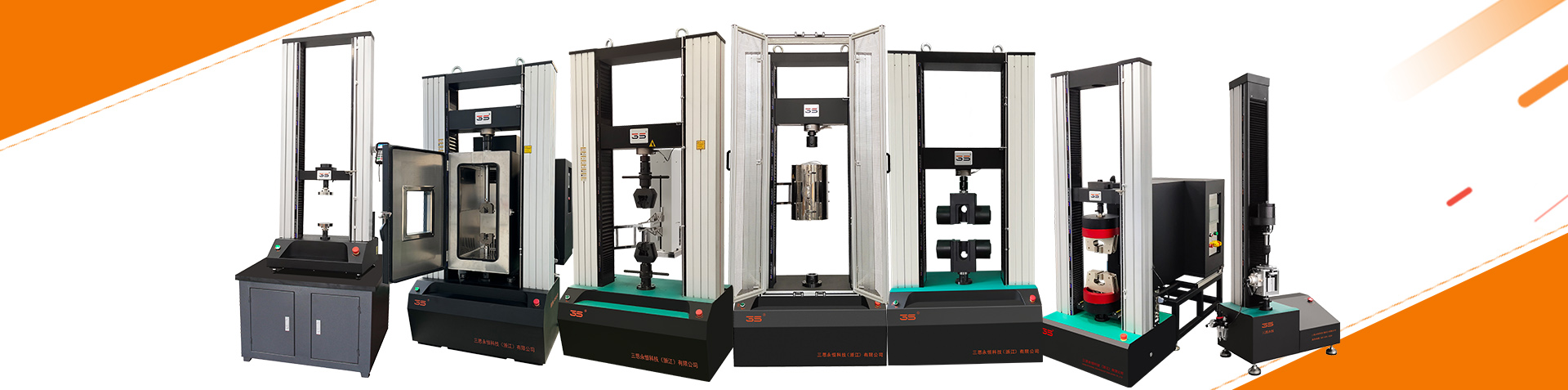

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument