Equipment name: Microcomputer-based plastic pendulum impact testing machine

Equipment model: ZBC1400C

Equipment Description: The microcomputer based plastic pendulum impact testing machine is a testing instrument used to test the performance of non-metallic materials such as plastics, nylon, hard rubber, fiberglass, electrical insulation materials, etc. in resisting impact under dynamic loads. This machine adopts semi-automatic control, which is easy to operate and has high work efficiency. Automatically obtain test data after impacting the specimen. Its superiority can be better demonstrated in laboratories that conduct continuous impact tests and manufacturers that conduct a large number of impact tests. The dedicated control panel and display screen equipped with this machine can meet the operational and display requirements of user testing, such as displaying impact absorption energy, impact strength, pendulum movement angle, and printing test reports. This machine can perform both simple supported beam tests and cantilever beam tests. The support adjustment and replacement are convenient, and it has strong applicability. It is an essential testing instrument for hard plastic manufacturers, quality inspection units, research institutes, and other institutions.

Execution standards:

GB/T 1043-2008 "Impact Test Method for Simply Supported Beams of Hard Plastics"

GB/T 1843-1996 "Impact Test Method for Plastic Cantilever Beams"

JB/T 8761-1998 "Plastic Cantilever Beam Impact Testing Machine"

JB/T 8762-1998 "Plastic simply supported beam impact testing machine"

ISO 179:2000 "Plastics-Determination of Charpy impact properties"

ISO 180:2000 "Plastics-Determination of Izod impact strength"

Main technical parameters:

1. Impact energy: simply supported beam 4J, 2J

Cantilever beam 4J, 2.75J

2. Pendulum moment: 2.1436N • m, 1.0718 N • m for simply supported beams

Cantilever beam 2.1436N • m, 1.4737 N • m

3. Pendulum pre lift angle: 150 º

4. Angle resolution: 0.1 º

5. Technical parameters of simply supported beams:

1) Impact speed: 2.9m/s

2) Distance from the center of the pendulum to the center of the specimen: 230mm

3) Blade angle: 30 °

4) Blade fillet radius: 2mm

5) Support fillet radius: 1mm

6) Front angle of support: 5 °

7) Rear angle of support: 10 °

8) Support span: 40mm, 60mm, 70mm

9) Sample type and size (length x width x thickness):

80mm x 10mm x 4mm

50mm x 6mm x 4mm

120mm x 15mm x 10mm

6. Technical parameters of cantilever beam:

1) Impact speed: 3.5m/s

2) Distance from the center of the pendulum to the center of the specimen: 335mm

3) Blade angle: 75 °

4) Blade fillet radius: 0.8mm

5) Blade front angle: 5 °

6) Blade back angle: 10 °

7) Distance between the center of the blade and the upper surface of the jaws: 22 ± 0.2 mm

8) Sample type and size (length x width x thickness):

80mm x 10mm x 4mm

63.5mm x 12.7mm x 12.7mm

63.5mm x 12.7mm x 6.4mm

63.5mm x 12.7mm x 3.2mm

7. Overall dimensions of the host (length x width x height): approximately 360mm x 240mm x 720mm

8. Host weight: approximately 70 kg

9. Host power supply: AC single-phase 220V ± 10% 50Hz 0.5kW

Optional device configuration:

1. Simple supported beam pendulum: 2J

2. Cantilever beam pendulum: 2.75J |

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

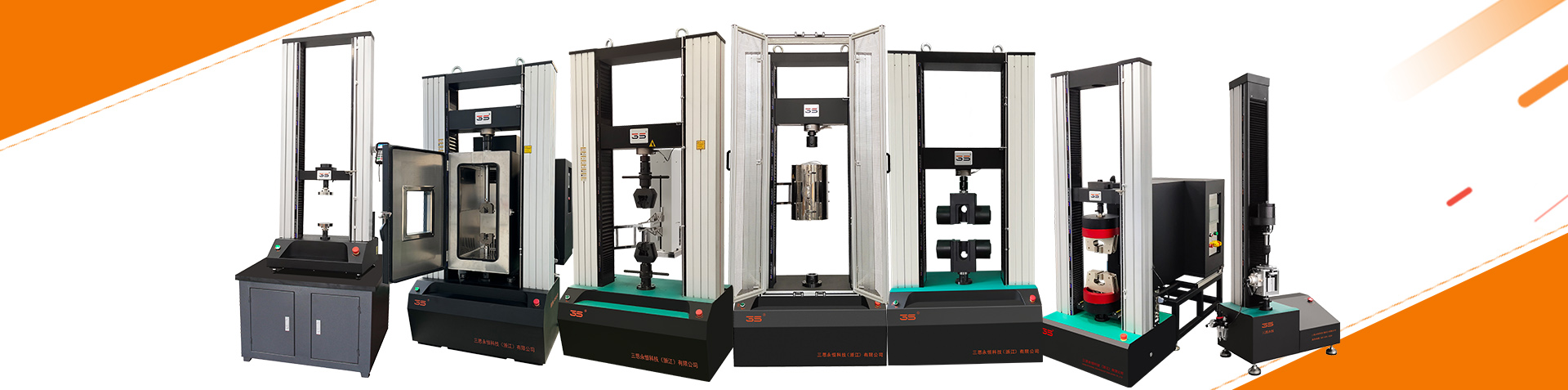

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument