Equipment name: Microprocessor controlled electronic universal testing machine

Product models: XBD2000A

Main functions of the equipment: This machine is used for testing and analyzing the static mechanical properties of metal and non-metal (including composite materials) adhesives, adhesive tapes, stickers, medical adhesives, protective films, release papers, composite films, food plastic bag packaging, daily cosmetic plastic packaging, artificial leather, woven bags, films, and paper in terms of tension, compression, bending, shearing, peeling, tearing, load holding, relaxation, and reciprocating, and can calculate the tensile strength Parameters such as bending strength, compressive strength, elastic modulus, fracture elongation, yield strength, etc. And can conduct tests and provide data according to relevant domestic and international standards such as GB, ISO, DIN, ASTM, JIS, etc.

Test standards met by the equipment:

Manufacturing standard for testing machines: GB/T 16491-2022 Electronic Universal Testing Machine;

Meet the testing method standards: GB/T1040-2006 "Determination of Plastic Tensile Properties" GB/T1041-2008 "Determination of Plastic Compressive Properties" GB/T9341-2008 "Determination of Plastic Bending Properties" GB/T13022-1991 "Test Methods for Plastic Film Tensile Properties" (Users can provide relevant testing standards, not exceeding 5)

The main components of the equipment are:

(1) Mechanical process structure:

The main frame is mainly composed of a base, three pillars, and a lead screw to form a single arm frame structure; The transmission loading system adopts an AC servo motor and a synchronous toothed belt deceleration device, which drives the high-precision ball screw to rotate and then drives the moving crossbeam to achieve loading. This machine has a beautiful appearance, good stability, high rigidity, high control accuracy, high work efficiency, low noise, and is energy-saving and environmentally friendly.

(2) Control and measurement system:

This machine adopts an advanced fully digital closed-loop control system for control and measurement, and uses a computer to dynamically display the test process and test curves, as well as perform data processing. After the experiment is completed, the curve can be magnified through a graphics processing module for data analysis and editing, achieving superior performance.

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

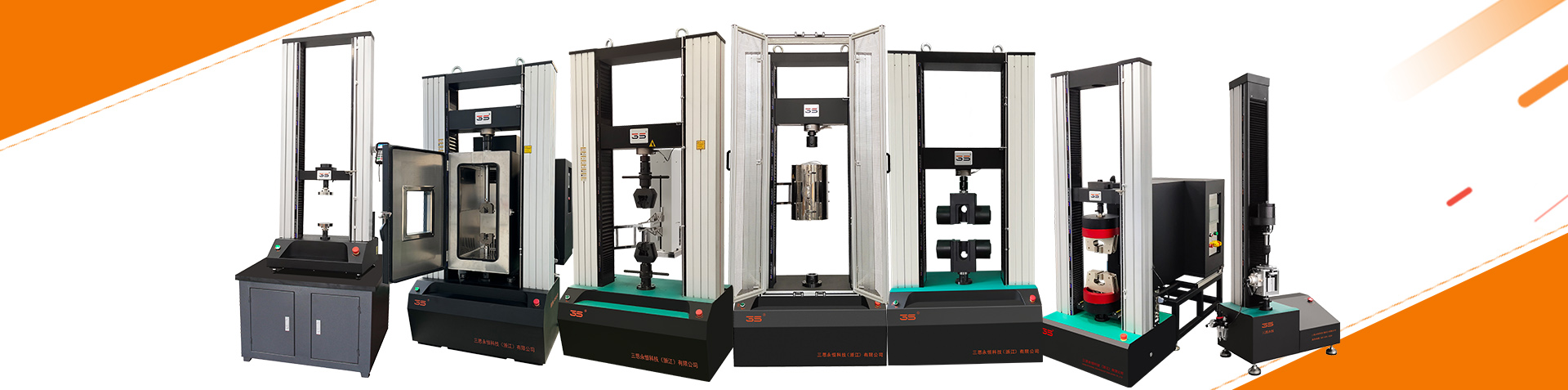

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument