Equipment name: Microprocessor controlled electronic universal testing machine

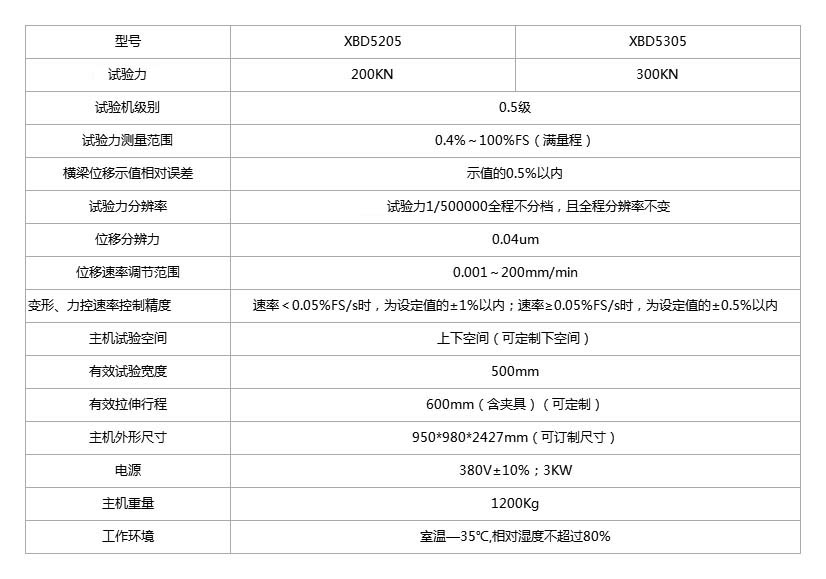

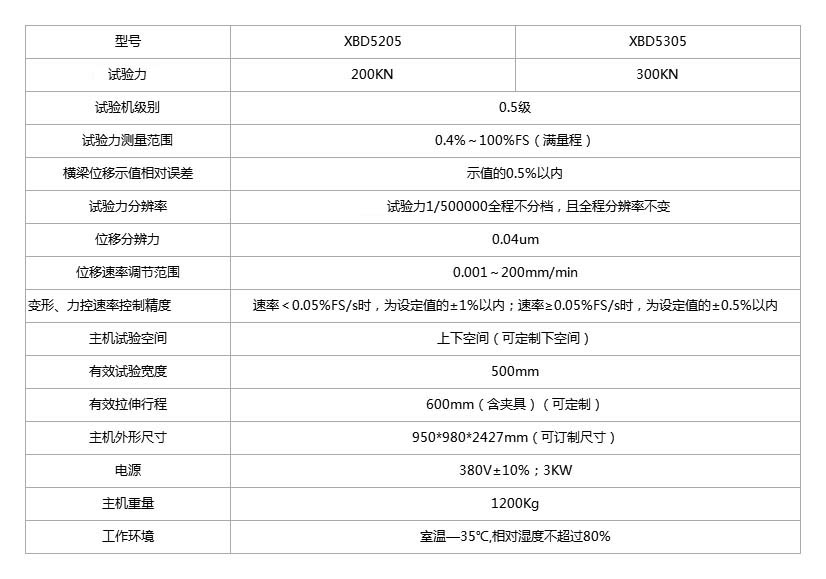

Product models: XBD5205, XBD5305

Main functions of the equipment: This equipment is suitable for testing the mechanical properties of metal materials, non-metallic materials, and composite materials, as well as analyzing and researching the process performance. Equipped with corresponding fixtures, it can perform tests such as tension, compression, bending, shearing, tearing, peeling, bursting, and fatigue. It can automatically calculate parameters such as test force, fracture force, elongation, tensile strength, yield strength, compressive strength, elastic modulus, shear strength, tear strength, peel strength, etc. At the same time, it can also achieve testing requirements such as constant elongation stress, constant stress elongation, and load retention. This machine is widely used for material inspection and analysis in industries such as building materials, aerospace, mechanical manufacturing, wires and cables, rubber and plastics, automotive manufacturing, powder metallurgy, fasteners, etc. It is an ideal testing equipment for scientific research institutions, colleges, industrial and mining enterprises, technical supervision, commercial inspection and arbitration, and other departments.

Experiments can be conducted according to standards such as GB, ASTM, DIN, ISO, JIS, BS, etc.

Manufacturing standard for testing machines: GB/T 16491-2022 Electronic Universal Testing Machine

GB/T 228-2010 "Metallic Materials Room Temperature Tensile Test Method" GB/T 232-2010 "Metallic Materials Bending Test Method" GB/T 7314-2007 "Metallic Materials Room Temperature Compression Test Method" (Users can provide relevant test standards, no more than 5)

Product details:

The XBD5000 portal microcomputer controlled electronic universal testing machine is a new type of material testing machine that combines electronic technology and mechanical transmission. It has a wide and accurate loading speed and force measurement range, high accuracy and sensitivity in measuring and controlling loads, deformations, and displacements. It can also perform automatic control tests for constant speed loading, deformation, and displacement, and has the function of low cycle load cycling, deformation cycling, and displacement cycling. There are multiple optional machine models available, including space models, pull-up and pull-down dual space models, and pull-up and pull-down dual space models. Environmental boxes and high-temperature furnaces can be added for environmental testing.

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument