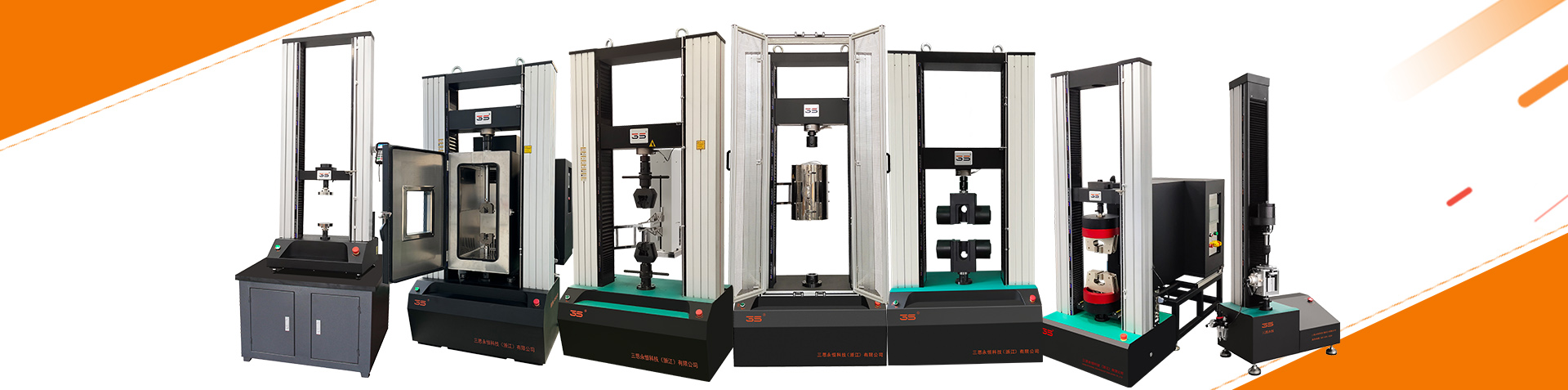

Device Name:Microcomputer controlled electronic universal testing machine

Product model:XBD6502、XBD6103、XBD6203、XBD6503、XBD6104、XBD6204

Main functions of the device:This equipment is suitable for testing the mechanical properties and analyzing the process performance of metal materials, non-metallic materials, and composite materials. Equipped with corresponding fixtures, it can perform tests such as tension, compression, bending, shearing, tearing, peeling, bursting, and fatigue. It can automatically calculate parameters such as test force, fracture force, elongation, tensile strength, yield strength, compressive strength, elastic modulus, shear strength, tear strength, peel strength, etc. At the same time, it can also achieve testing requirements such as constant elongation stress, constant stress elongation, and load retention. This machine is widely used for material inspection and analysis in industries such as construction materials, aerospace, mechanical manufacturing, wires and cables, rubber and plastics, automotive manufacturing, powder metallurgy, bolts, etc. It is a conceptual testing equipment for scientific research institutions, colleges and universities, industrial and mining enterprises, technical supervision, commercial inspection and arbitration, and other departments.

Experiments can be conducted according to standards such as GB, ASTM, DIN, ISO, JIS, BS, etc.

Test standards met by the equipment:

Manufacturing standard for testing machines: GB/T 16491-2022 Electronic Universal Testing Machine;

Meet the test method standards: GB/T1040-2006 "Determination of tensile properties of plastics" GB/T1041-2008 "Determination of compressive properties of plastics" GB/T9341-2008 "Determination of bending properties of plastics" GB/T 228-2010 "Room temperature tensile test method for metallic materials" GB/T 7314-2007 "Room temperature compression test method for metallic materials" (users can provide relevant test standards, no more than 5)

The main components of the equipment are:

The XBD6000 series microcomputer controlled electronic universal testing machine is an electromechanical integrated product, mainly composed of a host (including frame, base, transmission system), fixtures, deformation measurement system, software system, and electrical system.

Overview of product features:

frame

Strong self-lubricating guiding light rod increases the lateral rigidity of the equipment, ensuring linear movement of the crossbeam

It can accurately align the cross joint, ensure coaxiality, and reduce differences in measurement data

The key load-bearing components are made of cast steel as a whole to ensure the overall stiffness of the frame.

The grinding level preloaded ball screw and heavy-duty bearing ensure long-term zero clearance operation of the equipment, low noise, accurate test results, and good repeatability.

Host appearance: Adopting spray oxidation technology, the mold is formed in one go, which is beautiful and elegant.

Measurement sensor: Adopting imported high stability and high precision strain gauge load sensor; A highly stable precision measurement system ensures constant resolution throughout the entire process, ensuring that the error of the test force indication does not exceed ± 0.5%; Multiple load sensors can be used in different ways to achieve multi range measurement of test force range; Good temperature compensation, high sensitivity, high rigidity, and good long-term stability.

Compact design saves vertical testing space

Safe load: 150% of rated load

Excellent linearity under tensile and compressive loads

High vertical and horizontal rigidity

Load sensors range from 0.4% of their capacity to full range with no accuracy loss

The load accuracy is 0.5% of the indicated load

Fixture: a universal and specialized fixture for various materials, with convenient operation and reliable clamping. Can be configured with pneumatic and hydraulic fixtures, greatly improving work efficiency. The clamping force is adjustable to meet the testing requirements of users for different materials.

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument