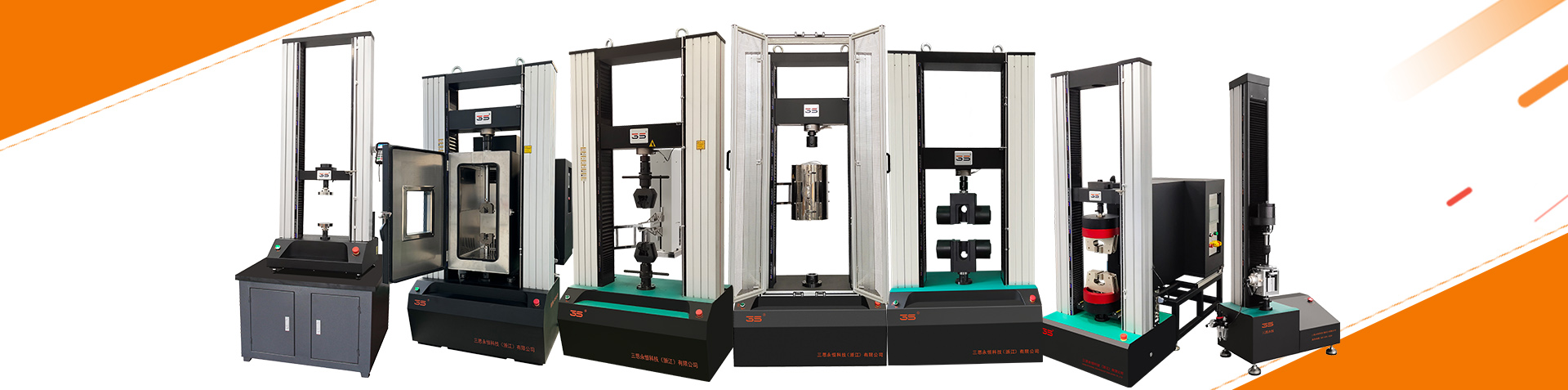

Device Name:Microcomputer-controlled electro-hydraulic servo universal testing machine

Equipment model:XBY4305S(D)/XBY4605S(D)/XBY4106SD/XBY4206SD

Equipment Overview:This testing machine is an important instrument and equipment for testing the physical properties, mechanical properties, process performance, structural seismic strength, and internal and external defects of various materials and their products in various environments and simulated states. It can achieve closed-loop control such as constant rate loading, constant rate deformation, constant rate displacement, and constant rate strain. During the experiment, the three control methods can be smoothly switched according to the set program. Testing of tensile, compressive, bending, shear and other types of metal or non-metallic materials can be carried out according to corresponding standards. The software can automatically calculate parameters such as ReH (upper yield strength), ReL (lower yield strength), Rp0.2 (specified non proportional elongation strength), Rt0.5 (specified total elongation strength), Rm (tensile strength), E (elastic modulus), etc. Conduct tests and provide testing data in accordance with international standards such as GB, ISO, JIS, ASTM, DIN, etc. It is possible to conduct process qualification performance verification tests on materials or products.

The XBY4605SB microcomputer controlled electro-hydraulic servo universal testing machine adopts a single space oil cylinder downward structure. Adopting a bidirectional differential oil cylinder to achieve bi-directional control of tension and compression in one space, suitable for situations mainly involving tensile tests.

The testing machine adopts a seamless rigid structure, which directly uses the lifting of the piston to adjust the testing space, making operation convenient and efficient. A closed-loop servo control system composed of an electrical controller, servo valve, force sensor, displacement sensor, extensometer, and computer can automatically and accurately control the test process, and automatically measure test parameters such as force, displacement, and deformation.

This testing machine is mainly used for tensile testing of metal materials, which can achieve control processes such as constant rate loading, constant rate deformation, and constant rate displacement. It can also achieve three-stage control of force, deformation, and displacement in a single test, with smooth conversion between each control.

The computer and measurement and control system collect test data and send control instructions, which can automatically control the test process and calculate the test results. The test curve and test results are displayed in real time on the microcomputer screen, and the test report and test curve are printed by the printer. The system has a return function, and after the test is completed, the loading cylinder piston can automatically or manually return to its initial position.

The experimental data can be transmitted to the network through a data interface. Related instructions: Our software can provide network interfaces in advance according to user requirements; If it involves dispatching software personnel to provide on-site services to users, corresponding fees will be charged; We only assist users in networking work and do not assume the responsibility of negotiating or coordinating with relevant network companies.

It can meet the special testing requirements of users (if necessary, relevant fixtures and deformation measurement devices can be configured separately).

Applicable standards:GB/T 16826-2008 Electrohydraulic Servo Universal Testing Machine

GB/T 16825.1-2008 "Inspection of static uniaxial testing machines - Part 1: Inspection and calibration of force measurement systems for tensile and/or pressure testing machines"

GB/T 22066-2008 "Evaluation of Computer Data Acquisition Systems for Static Uniaxial Testing Machines"

JJG 139-1999 "Tensile, compressive, and universal material testing machines"

JB/T 6146-2007 Technical Conditions for Extensometers

GB/T 228.1-2010 "Metallic Materials - Tensile Testing Methods"

GB/T 7314-2005 "Test Method for Room Temperature Compression of Metallic Materials"

GB/T 232-2010 "Bending test method for metallic materials"

|

Pendulum impact testing machine

Pendulum impact testing machine Plastic specific testing machine

Plastic specific testing machine Automated testing plan

Automated testing plan torsion testing machine

torsion testing machine Coulomb thickness gauge

Coulomb thickness gauge Dynamic fatigue testing machine

Dynamic fatigue testing machine Electronic universal testing machine

Electronic universal testing machine Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine Horizontal tensile testing machine

Horizontal tensile testing machine High temperature creep endurance testing machine

High temperature creep endurance testing machine Metallographic auxiliary consumables

Metallographic auxiliary consumables Xinbiao Instrument

Xinbiao Instrument