CN

Products

-

Pendulum impact testing machine

Pendulum impact testing machine -

Plastic specific testing machine

Plastic specific testing machine -

Automated testing plan

Automated testing plan -

torsion testing machine

torsion testing machine -

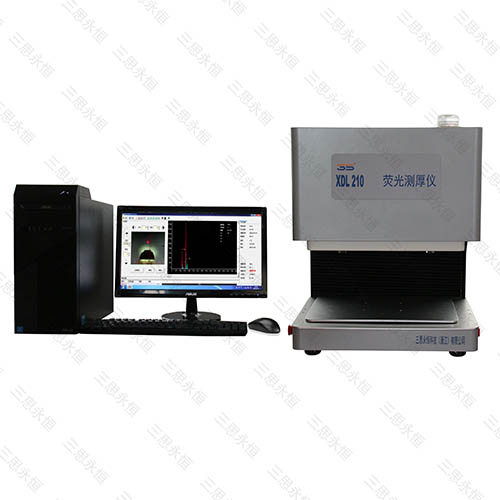

Coulomb thickness gauge

Coulomb thickness gauge -

Dynamic fatigue testing machine

Dynamic fatigue testing machine -

Electronic universal testing machine

Electronic universal testing machine -

Electro hydraulic servo universal testing machine

Electro hydraulic servo universal testing machine -

Horizontal tensile testing machine

Horizontal tensile testing machine -

High temperature creep endurance testing machine

High temperature creep endurance testing machine -

Metallographic auxiliary consumables

Metallographic auxiliary consumables -

Xinbiao Instrument

Xinbiao Instrument

-

Accessories

Testing Solutions

News

About Us

Service support

Contact Us